TraverseBoard Advanced Planning & Scheduling

Simulation-assisted planning & scheduling software

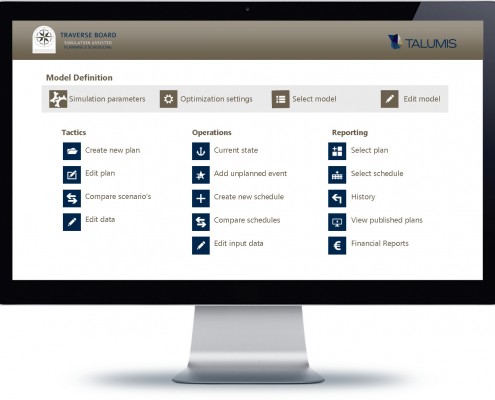

TraverseBoard Advanced Planning & Scheduling is a custom made software tool to enable design, tactical and operational decisions through multiple time horizons.

Traverse Board’s calculation core consist of simulation models strengthened with optimization algorithms brought together by a customizable user-friendly interface. The tool is typically used in high risk and high investment businesses.

Integrating optimization techniques and simulation

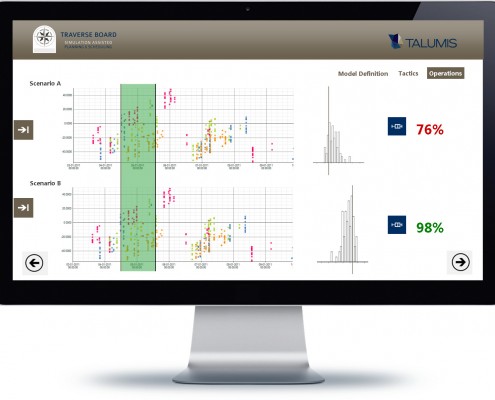

TraverseBoard can be used to create optimized day-to-day schedules and plans but is also able to analyze investment scenarios. By combining the unique strengths of both simulation and optimization, fast, reliable, robust and accurate results are created.

Traverse board is a comprehensive platform for creating optimized robust plans and schedules through multiple time horizons.