Introduction: Concrete Production Simulation Library

The HESS Group is an international concrete products machine manufacturer. A long-term policy of continuous innovation, and the uncompromising application of future-oriented technologies are what help maintain the HESS Group’s current position as a worldwide supplier to the concrete industry of complete systems. The HESS Group approached Talumis to support them with simulation to gain insight and optimise their logistics when setting up a concrete production system.

Objective

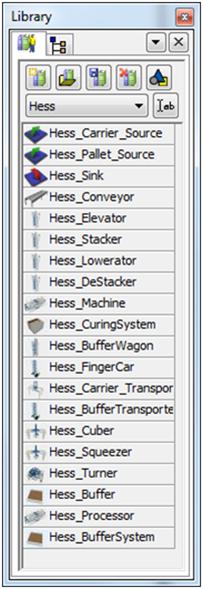

The HESS Group has asked Talumis to create a concrete production library in FlexSim. With this library the HESS Group is able to create, analyze and optimize their production systems and convince their clients of the designed layout and solution for the scope of their production system.

Solution

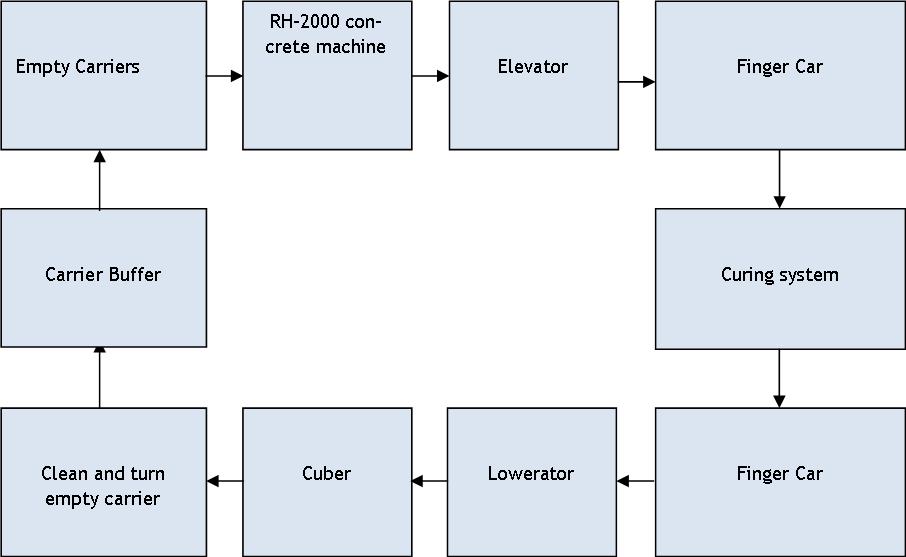

Talumis designed a concrete production library in FlexSim by first analyzing the objects and functionality needed to create a production layout with minimum effort. The typical production process (figure 1) designed by the HESS Group was used as a guideline to built the production library. On the right the end result of the concrete production library is depicted.

Results

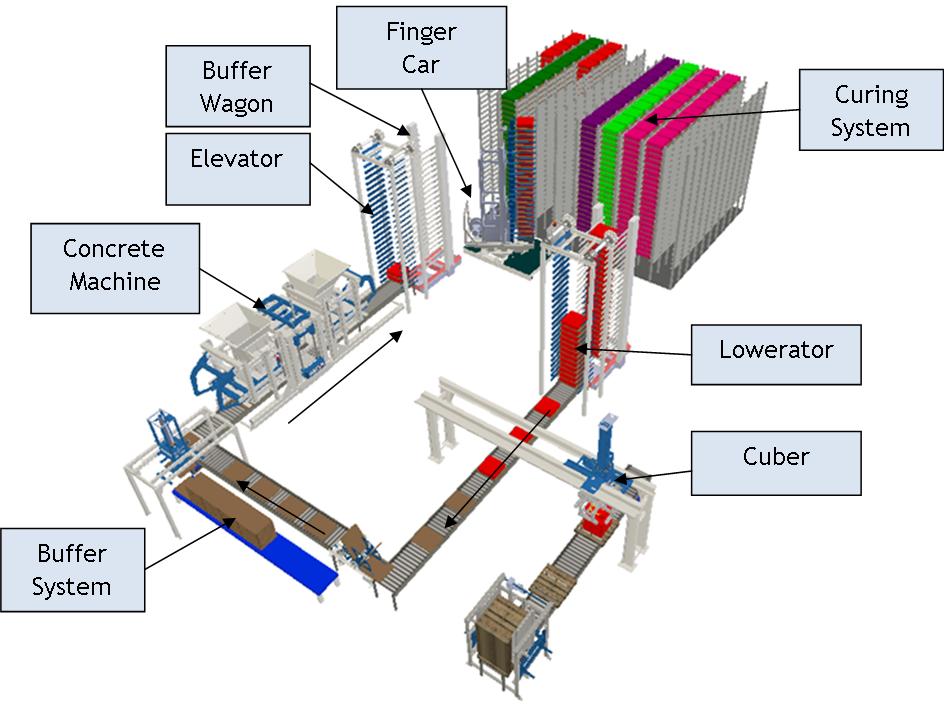

This project resulted in and easy to use concrete production library for the HESS Group. As an example a basic layout is depicted in figure 2. This layout consists of a ‘concrete machine’ pressing the layers of concrete onto the empty carriers in a mould. The carrier with concrete is then transported and stacked into an ‘elevator’. A complete stack is transported via a ‘bufferwagon’ and a ‘finger car’ into a curing system. There, the stacks dry for a certain amount of time. After drying, the stacks are picked up by the same ‘finger car’ and transported via a ‘bufferwagon’ to a ‘lowerator’ where the carriers with concrete are de-stacked at the palletizing side (or dry side). At the palletizing position the layer of concrete is picked up by a ‘cuber’ and placed onto a pallet. The empty carrier continues and gets turned at the end of the Conveyor.

Created with drag and drop functionality of the library

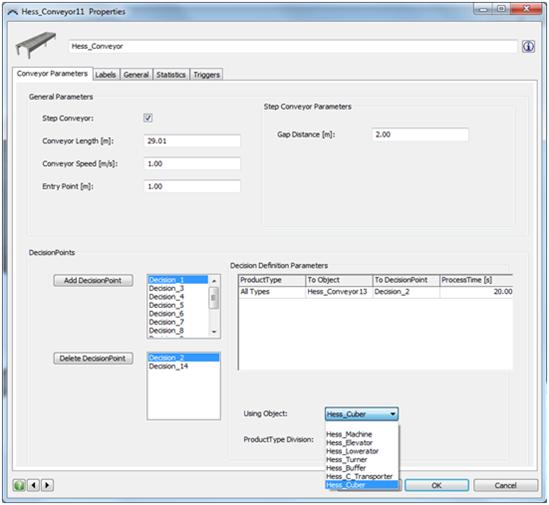

The system was easily created with a drag and drop functionality of the library combined with setting up the GUIs (Graphical User Interface). Especially the GUI used on the conveyor object lets the user quickly set up the needed functionality of the production system by means of certain so called decision points. In the example on the right the Cuber object (which has already been dragged into the model) is selected for the fourth decision point. Also, the receiving conveyor has the second decision point as the destination of the concrete layer. Automatically the objects are placed on the correct position and the system knows how to palletize the layers of concrete.

Conclusion

This project is a clear example of custom-built library, which is one of the expertises of Talumis. Although FlexSim is an easy to use program and has many features, it is possible that for your specific industry a custom-built library is the solution to help you understand your logistic problems and to convince your clients of your solutions.

Watch the Hess Group Production Simulation Video

Steven Hamoen

Ask Steven a question

Want to optimize your Production Line with Talumis Simulation?

More information how Talumis can help optimize your production flows and processes ? Ask our production expert Steven Hamoen.